WHAT DO AIRCRAFT MECHANICS DO?

One day soon, we’ll all be riding jetpacks to work, because it’s the 21st century and WE WERE PROMISED JETPACKS, DANG IT! Until that day, we have to content ourselves with last century’s boring flying machines: planes and helicopters. To keep those aircraft working correctly, the world needs aircraft mechanics. And in the very near future who do you think will be needed to repair drones and electricity generating windmills and their components?

Aircraft mechanics maintain and repair the avionic and mechanical equipment needed to make planes and helicopters operate safely. This includes repairing, inspecting and maintaining the structural, mechanical and electronic elements of the aircraft, replacing parts, measuring wear and assessing whether parts need repair or replacement. Aircraft mechanics use a wide variety of diagnostic devices, computers, hand and mechanical tools to assess and fix aircraft, and maintain aircraft standards as required by the Federal Aviation Administration (FAA). Mechanics can specialize in a specific form of aircraft or be a generalist, and most will have an FAA Airframe and Powerplant (A&P) certificate. After being successful in school, the companies that hire you will provide the training required to work and maintain there specific fleet or equipment. But, when taking that training you are being paid!

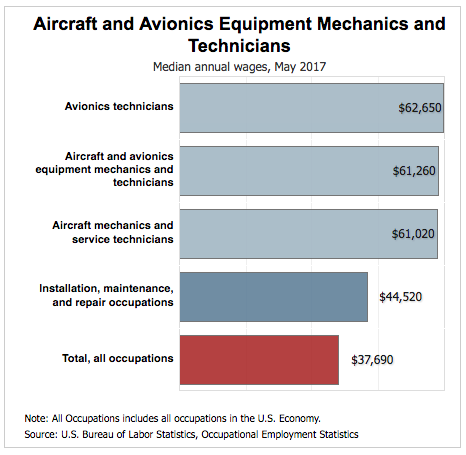

HOW MUCH DO AIRCRAFT MECHANICS MAKE?

The Bureau of Labor Statistics (BLS) states that the median income for aircraft mechanics in 2017 was $29.45 per hour, or $61,260 per annually.

WHAT ARE THE EDUCATION REQUIREMENTS?

You must learn your skills in a FAA certified aviation maintenance tech school. The course last around 2 years. Additionally, some of these schools offer 2 or 4 year degrees in avionics, aviation maintenance management or aviation tech. Bachelor degrees are becoming more and more important to employers, and you may be well served to get your Bachelor’s degree.

WORK ENVIRONMENT

Aircraft and avionics equipment mechanics and technicians work in hangars, in repair stations, or on airfields. They must often meet strict deadlines to maintain flight schedules. The environment can be loud because of aircraft engines and equipment. Workers frequently bend, stoop, and reach from ladders and scaffolds. Most mechanics and technicians work full time; overtime and weekend work is common.

JOB SKILLS AND REQUIREMENTS

- Attention to Detail: Airplanes need to be maintained to very specific standards. Being precise and making sure things are repaired exactly right is key.

- Dexterity: Aircraft mechanics need to use their hands to manipulate and work with a number of components.

- Technical Skills: Aircraft mechanics need to be able to read gauges, understand instrumentation and diagnostic tools when assessing and repairing aircraft.

- Troubleshooting: Mechanics need to be able to understand the root causes of aircraft problems and how to correct those problems.

Aircraft mechanics typically do the following:

- Examine replacement aircraft parts for defects

- Diagnose mechanical or electrical problems

- Read maintenance manuals to identify repair procedures

- Repair wings, brakes, electrical systems, and other aircraft components

- Replace defective parts using hand tools or power tools

- Test aircraft parts with gauges and other diagnostic equipment

- Inspect completed work to ensure that it meets performance standards

- Keep records of maintenance and repair work

Avionics technicians typically do the following:

- Test electronic instruments, using circuit testers, oscilloscopes, and voltmeters

- Interpret flight test data to diagnose malfunctions and performance problems

- Assemble components, such as electrical controls and junction boxes, and install software

- Install instrument panels, using hand tools, power tools, and soldering irons

- Repair or replace malfunctioning components

- Keep records of maintenance and repair work

Advancement

As aircraft mechanics gain experience, they may advance to lead mechanic, lead inspector, or shop supervisor. Opportunities are best for those who have an aircraft inspector’s authorization (IA). Many specialist certifications are available that allow mechanics to do a wider variety of repairs and alterations.

Mechanics with broad experience in maintenance and repair might become inspectors or examiners for the FAA.

Additional business and management training may help aircraft and avionics equipment mechanics and technicians open their own maintenance facility.